Printing Does Not Start/Printing Is Blurred/Colors Are Wrong/Straight Lines Are Misaligned

13-Mar-2008

8200133700

Issue

Cause and Solution

Open the Top Cover of the printer to confirm how the ink lamps light or flash, and then take the appropriate action depending on the error condition. For details, see[ Getting the Ink Status Information ].

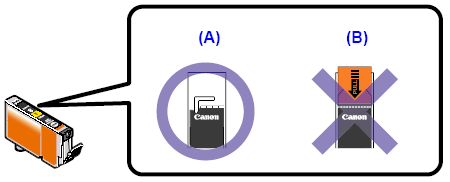

Make sure all of the orange tape is peeled off the ink tank and the air hole is exposed, as illustrated in (A). If any orange parts are left as in (B), remove all of the orange parts.

(A) Correct

L-shaped air hole is exposed.

(B) Incorrect

Part of the orange tape is remaining. Peel off the tape properly along the perforation.

See[ Printing the Nozzle Check Pattern ] and perform any necessary maintenance operation.

Print Head Cleaning

Clean the Print Head if lines are missing or if white streaks appear in the printed nozzle check pattern. Cleaning unclogs the nozzles and restores the print head condition. Note that cleaning the Print Head causes used ink to be absorbed in the ink absorber. Cleaning the Print Head consumes ink, so perform Print Head Cleaning only when necessary.

See[Print Head Cleaning]

Print Head Deep Cleaning

If print quality does not improve by standard Print Head Cleaning, try Print Head Deep Cleaning, which is a more powerful process. Note that cleaning the Print Head causes used ink to be absorbed in the ink absorber. Print Head Deep Cleaning consumes more ink than standard Print Head Cleaning, so perform this procedure only when necessary.

See[Print Head Deep Cleaning ]

Many types of paper are made to be printed on only a particular side of the paper.

Printing on the wrong side may cause unclear prints or prints with reduced quality.

Refer to the instruction manual supplied with the paper for detailed information on the printable side.

If you did not align the Print Head after installation, straight lines may be printed misaligned. If ruled lines are printed misaligned or print results are otherwise unsatisfactory, see[ Aligning the Print Head ] and perform Print Head Alignment.