Key Features

AI-Powered Features

AI Precision

Canon's AI technology detects cracks and defects with unparalleled accuracy, minimizing the risk of human error. This advanced AI system learns from vast datasets, enabling it to identify even the smallest anomalies that might be missed during manual inspections.

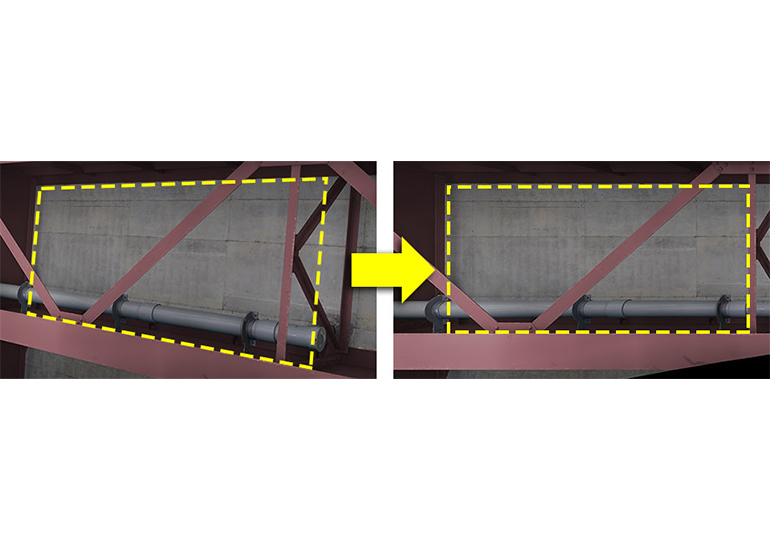

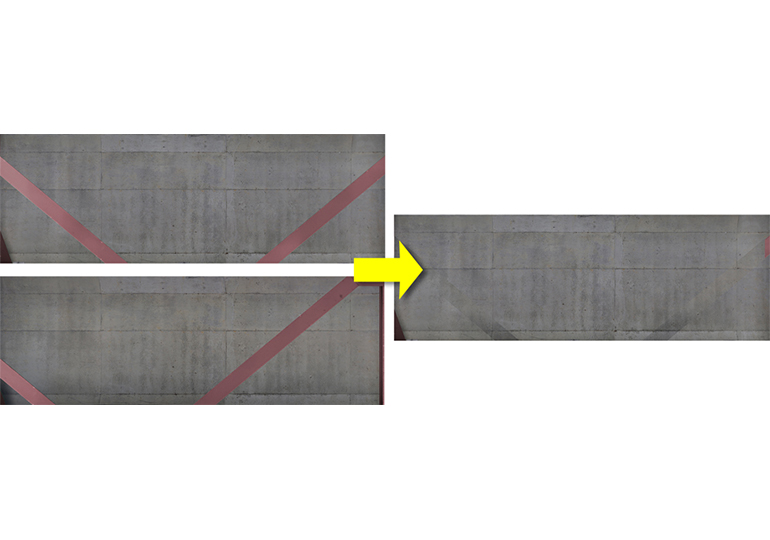

Image of chalk marks drawn by the engineer during visual checks.

Result of automatic crack detection using Canon’s Crack Detection technology.

Comprehensive Defect Detection

Efficiency

Custom AI Models

Enhancing Productivity

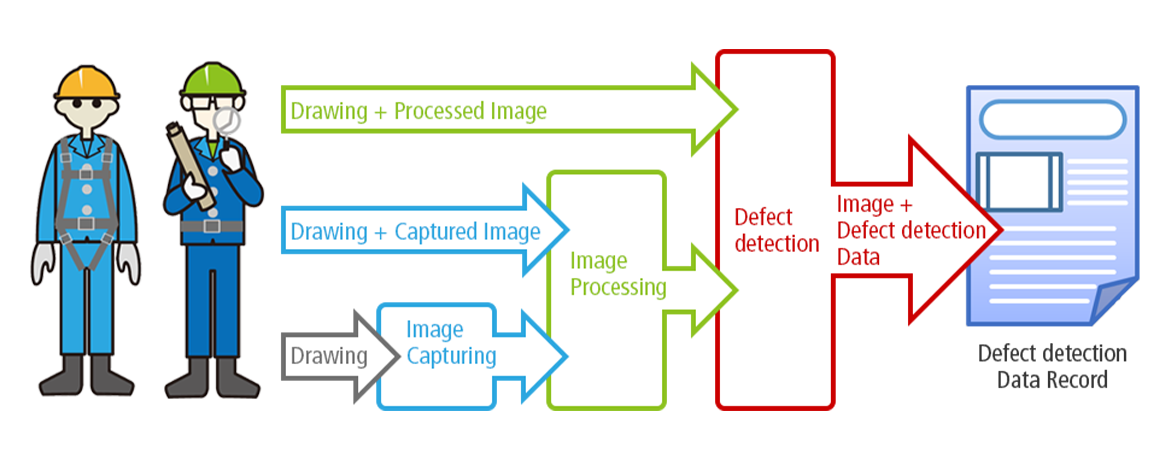

1. Image Capture: Uses Canon’s DSLR cameras and drones to capture high-resolution images, identifying cracks as small as 0.2 mm.

2. Image Processing: Corrects image tilt and overlays images onto structural drawings for precise crack evaluation, merging multiple angles to remove obstructions.

3. Defect Detection: Employs AI and deep learning to detect and measure crack width with 99.5% accuracy, differentiating cracks from dirt and joints.

This system enhances inspection precision and efficiency.

Detectable Defects

Efflorescence

Delamination

Rusty Water

Exposed Rebar

Water Leakage

Cracks & Rusting (Wind Power Blades)

Cracks (Solar Panels)

Envision Smart Surveillance Together With Canon Today!

Click here to contact us to find out more.

Solutions Videos

Related Pages

Related Products

Product Disclaimer

- 01. Prices, specifications, availability and terms of offers may change without notice.

- 02. Products / Services may be manufactured by and/or supplied to us by third party manufacturers / suppliers for distribution / resale (non-Canon brand products).

- 03. Prices above are recommended retail price in SGD and may change without prior notice.