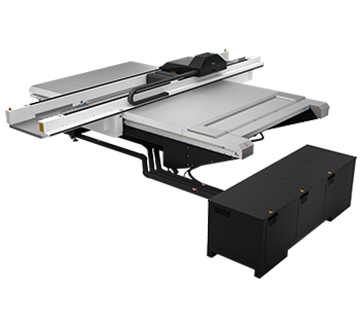

Arizona 6160 XTHF Mark II

Arizona 6160 XTHF Mark II

This addition to the world-leading, award-winning Arizona flatbed series sets the standard for speed, reliability, automation, ease-of-use, rigid media application versatility and high-quality productivity.

A high-volume, fully integrated, Arizona High-FLOW technology flatbed printer that is particularly effective when the substrate does not adequately seal the vacuum area, for instance for porous corrugated cardboard or severely warped plywood.

Key Features

Certificates

Features

Consistent High Productivity

Experience high print speeds with fast, repeatable registration with substrate handling. Continuous printing capabilities ensure minimum downtime and exceptional first-time-right productivity. Achieve non-stop production on the extra-large, dual-origin flatbed table. Designed for operational ease-of-use and fast and easy loading/unloading.

Maximum Uptime

A highly dependable printer that's built to last. The standard Automated Maintenance System provides completely automated, hands-free printhead cleaning for maximised uptime and continuous outstanding quality.

Excellent Print Quality

Realise unrivalled photo-realistic print quality with fast, reliable inkjet production at up to 220 m2 per hour.

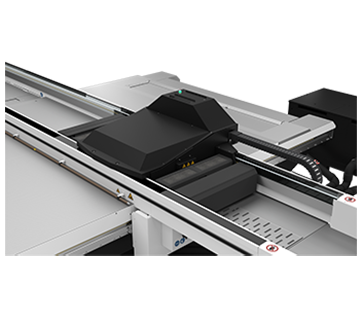

Unique Technology

VariaDot Imaging Technology

VariaDot imaging technology allows piezoelectric printheads to produce droplets of varying volume on demand. This allows the connected workflow software to specify an appropriate droplet size for each specific image feature. When rendering fine detail such as small type or fine lines, very small droplets can be used, when rendering areas of tonal transition or quartertone values such as skin tones drops of medium volumes can be used and for areas of high density such as solid colours, large droplets can be used. Employing the 3rd generation of the award-winning VariaDot technology, the Arizona 6100 Mark II series offers photo-realistic print quality while using light inks for finer details and smoother gradients in even the fastest production modes.

Experience the Remarkable Flatbed Evolution

Workflow Solutions

The following workflow solutions are designed to help you get the most out of your printer.

PRISMAguide XL makes your workflow one smooth process. Simplify and automate advanced print jobs, including added-value, multi-stepped and double-sided applications, making high-quality print files ready in an instant.

ONYX Thrive workflow software offers print service providers a scalable print production solution based on Adobe® technologies. This enables a true end-to-end PDF workflow from digital file submission through colour management, printing and cutting.

Canon VarioDot Technology

Related Pages

Specifications

Specification

Printing |

|

Printing Method |

Piezoelectric inkjet using 3rd generation VariaDot imaging technology in a six colour configuration; arranged in six independent channels of six 636-nozzle variable droplet printheads per channel, 36 printheads in total. |

Ink Channels |

CMYK + cm |

Curing |

Halide |

Print Resolution |

Variable droplet sizes from 6 to 30 picoliters. The ability to vary the drop size to 6 picoliters produces sharp images with smoother gradients and quartertones. The ability to jet larger droplets up to 30 picoliters produces uniform colors. The result is photo-realistic print quality with sharpness only before seen at resolutions of 1,440 dpi or higher. Text as small as 6 pt. is perfectly legible. |

Printing Speed |

|

Printing Modes: |

|

High-Key |

Flatbed: 220 m²/h, 2368 ft²/h |

Express |

Flatbed: 155 m²/h, 1668 ft²/h |

Production-Fast |

Not available |

Production |

Flatbed: 100 m²/h, 1076 ft²/h |

Production Plus |

Flatbed: 100 m²/h, 1076 ft²/h |

Production Matte |

Flatbed: 72 m²/h, 775 ft²/h |

Quality |

Flatbed: 72 m²/h, 775 ft²/h |

Quality-Plus |

Flatbed: 72 m²/h, 775 ft²/h |

Quality-Matte |

Flatbed: 51 m²/h, 549 ft²/h |

Quality-Smooth |

Flatbed: 40 m²/h, 431 ft²/h |

Quality-Density |

Flatbed: 40 m²/h, 431 ft²/h |

Quality-Layered (2) |

Not Available |

Quality-Layered (3) |

Not Available |

Fine Art |

Not available |

High Definition |

Not available |

System Architecture |

True flatbed architecture optimized for printing on rigid or sheet media or objects, including corrugated cardboard and other porous or difficult to constrain media. |

Geometric Accuracy |

|

Measured Over |

Line Length (width): |

Maximum Error |

Line Length (system width): |

Media |

Maximum Area: 2,500 x 3,200 |

Rigid Media |

|

Rigid Media Print Area |

2,510 x 3,210 mm, edge-to-edge printing (full bleed) |

Roll Media |

Not applicable |

Roll Media Print Width |

Not applicable |

Software |

|

Image Processing |

ONYX® Thrive V21.0 or greater |

Environmental and Safe Use |

Greenguard and Greenguard Gold Certificates for IJC 255, IJC 261, IJC 262 Inks |

Accessories |

Not applicable |

Consumables |

Canon UV curable Inks, packed in quick-change ink bag

|

Product Disclaimer

- 01. Prices, specifications, availability and terms of offers may change without notice.

- 02. Products / Services may be manufactured by and/or supplied to us by third party manufacturers / suppliers for distribution / resale (non-Canon brand products).

- 03. Prices above are recommended retail price in SGD and may change without prior notice.