Canon Announces “Lithography Plus” Solution Platform Offering Canon’s Support Know-how

to Help Maximize Productivity for Semiconductor Lithography Systems

SINGAPORE, 5 September 2022 — Canon Inc. announced that the company will today begin offering the “Lithography Plus1,” solution platform for semiconductor lithography systems. The system incorporates Canon’s more than 50 years of expertise in semiconductor lithography system support and the company’s vast wealth of data collected to maximize support efficiency as well as propose and implement optimized system processes.

Canon offers expansive lineups of KrF semiconductor lithography systems, as well as i-line steppers that support a wide range of devices, and has a long history of providing user support for these systems. Lithography Plus leverages this accumulated know-how and data as a solution platform that both improves the efficiency of support operations and operational efficiency of lithography systems, thereby contributing to increased productivity for system users.

Canon’s Lithography Plus system includes functions that analyze the status of lithography systems, results of regular maintenance, causes of system downtime and other valuable information. System users can utilize this data to more easily create system operation plans during maintenance or parts replacement, thereby enabling appropriate maintenance. What’s more, the Dash Board function helps to further increase the efficiency of user maintenance work by providing a holistic view of all semiconductor lithography systems in operation at their worksite.

The Anomaly Detection function supervises system operational status and detects abnormalities and signs of potential trouble to prevent unexpected system shutdowns. In addition, an Automatic Restore function helps restart system operations. When automatic restoration is not possible, system restoration instruction are presented to operators in an easy-to-understand manner, thereby facilitating smoother recovery. What’s more, through a remote concierge service, system status can be shared with Canon’s expert engineers, helping them better understand the situation at hand and provide detailed assistance during customer support calls.

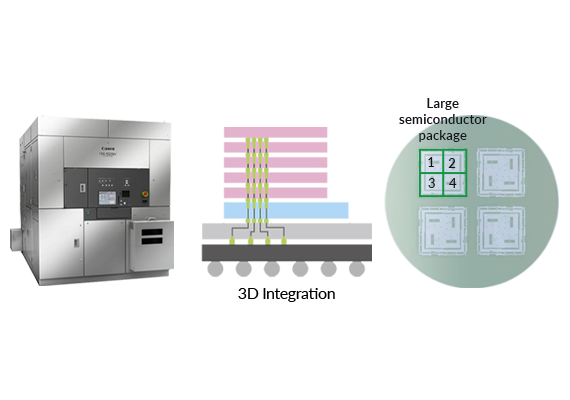

The Process Solution function provides a comprehensive collection of successful lithography system optimization recipes that Canon has accumulated over its long history in the business. By providing automated and optimized “recipe2” for configuring such settings as precise alignment accuracy and control of line width, enabling even newly implemented semiconductor lithography processes to realize high yield rates3, thus supporting increased system productivity. Lithography Plus also has the ability to interface with AP4 and other process equipment, making possible greater coordination with manufacturing management systems.

About Canon Singapore Pte. Ltd.

Canon is a global leader in photographic and digital imaging solutions. Canon Singapore Pte. Ltd. is the headquarters for South & Southeast Asia driving sales, marketing and service strategies. Besides handling the domestic market, the company covers 22 other countries and regions including subsidiaries in India, Malaysia, Thailand and Vietnam. The parent company Canon Inc. has a global network of more than 300 companies and employs about 180,000 people worldwide. Canon is guided by its kyosei philosophy that focuses on living and working together for the common good.

More information is available at https://sg.canon.

1 For detailed specifications, please visit: https://global.canon/en/product/indtech/semicon/index.html.

2 Manufacturing conditions that vary depending on the device and type of manufacturing process.

3 The ratio of properly formed products to defective products in a manufacturing process.

4 Advanced Process Control. Refers to the use of optimized processing parameters for individual lots. Results of past processes are applied and used for such purposes as predicting values in front-end processes, advanced statistical and analytical techniques to manipulate process control parameters and inputs on process tools to improve output quality.